Heavy Duty Round Bar Work Roll Alloy Steel Roller

Heavy Duty Round Bar Work Roll Alloy Steel Roller

A heavy-duty round bar work roll is a cylindrical component made from alloy steel, designed for use in rolling mills and metalworking processes. These rolls are essential for shaping and forming metals, particularly in the production of round bars and other profiles.

Applications:

Heavy-duty round bar work rolls are primarily used in:

Steel Mills: For rolling and shaping steel into round bars and other forms.

Aluminum Processing: In rolling mills to produce aluminum products.

Manufacturing: Utilized in various metal fabrication processes where high strength and durability are required.

Characteristics:

Material Composition: Typically made from high-quality alloy steels, which provide excellent strength, toughness, and wear resistance.

Design: Engineered to withstand high pressures and temperatures during the rolling process, ensuring consistent performance.

Surface Finish: Often treated to achieve a smooth surface, reducing friction and improving the quality of the finished product.

Benefits:

High Load Capacity: Capable of handling significant loads without deformation, making them suitable for heavy-duty applications.

Improved Wear Resistance: Alloy steel materials enhance the longevity of the rolls by resisting wear and tear during operation.

Thermal Stability: Designed to maintain performance under varying temperatures, which is crucial in rolling operations.

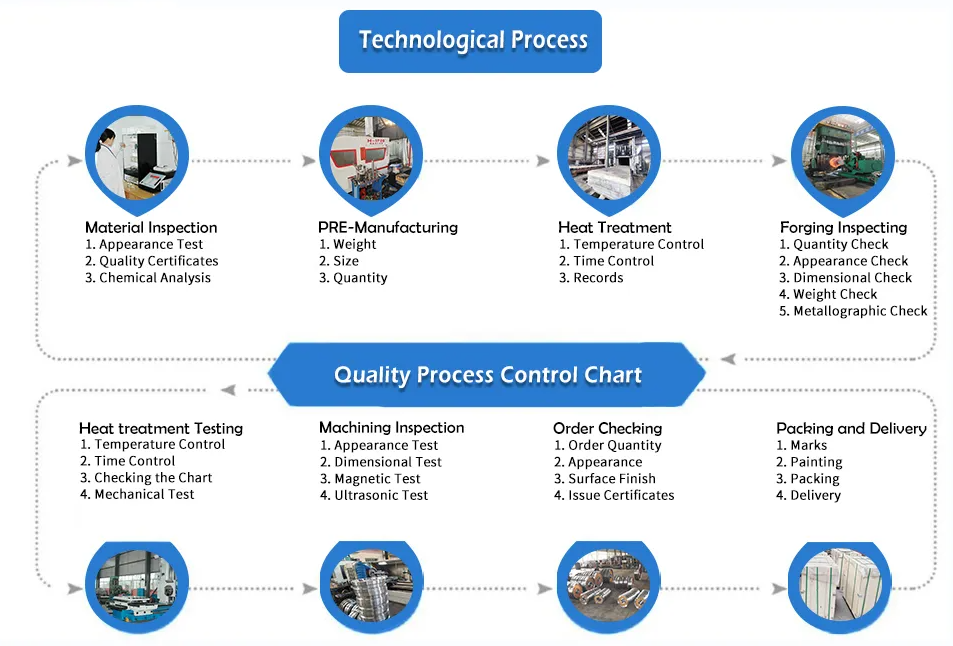

Manufacturing Process:

Material Selection: High-quality alloy steel is selected based on the specific requirements of the application.

Forging: The initial shape is created through forging, which improves the material's internal structure.

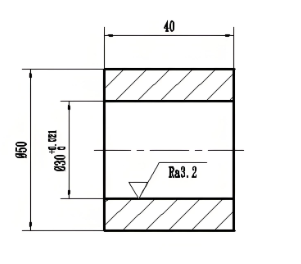

Machining: Precision machining is performed to achieve the desired dimensions and surface finish.

Heat Treatment: The rolls undergo heat treatment processes to enhance hardness and toughness.

Finishing: Final surface treatments may be applied to ensure optimal performance and durability.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :