Forged stainless steel sleeves

Forged stainless steel sleeves

1. Definition

Forged stainless steel sleeves are cylindrical components made through a forging process, designed to connect or reinforce pipes and other structures. They are known for their corrosion resistance and durability.

2. Materials

These sleeves are typically made from various grades of stainless steel, such as:

AISI 304: General-purpose stainless steel with good corrosion resistance.

AISI 316: Offers enhanced corrosion resistance, especially in marine and chemical environments.

AISI 410: Martensitic stainless steel used for applications requiring higher strength and moderate corrosion resistance.

3. Manufacturing Process

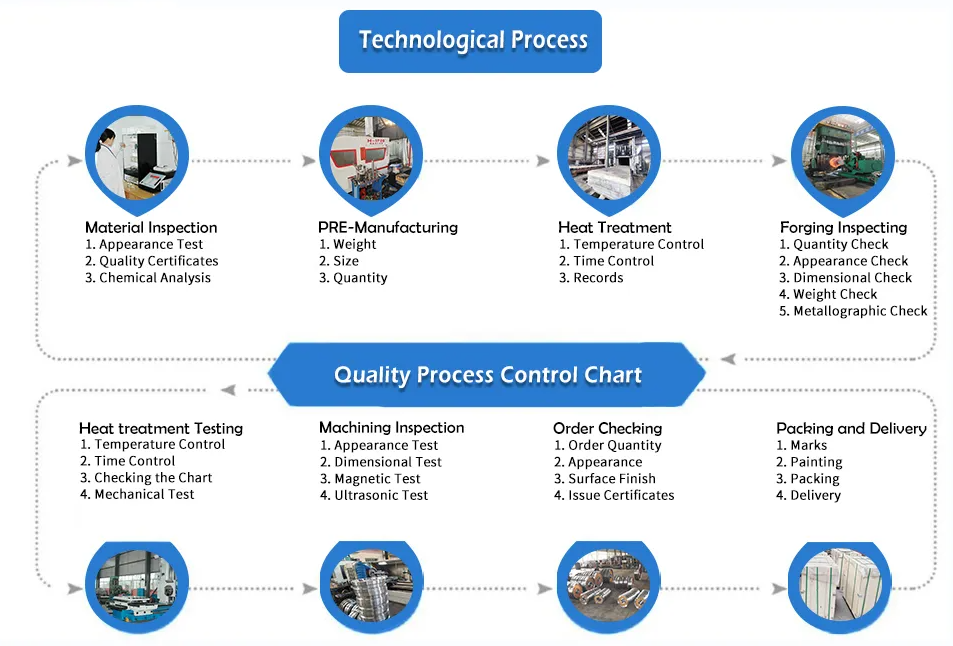

Forging: The stainless steel is heated to a malleable temperature and shaped under high pressure. This improves the material's mechanical properties and ensures a refined grain structure.

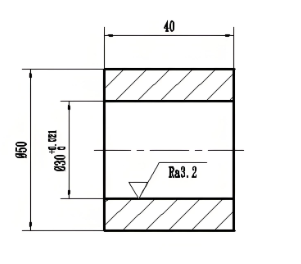

Machining: After forging, the sleeves may undergo machining to achieve precise dimensions and surface finishes.

Heat Treatment: Some grades may be heat-treated to enhance hardness and overall performance, though many stainless steels are used in their annealed state for optimal corrosion resistance.

4. Applications

Forged stainless steel sleeves are commonly used in:

Piping Systems: To connect or reinforce pipes in various industries, including oil and gas, water treatment, and food processing.

Automotive: In exhaust systems and other components where corrosion resistance is critical.

Industrial Equipment: In machinery components that require durability and resistance to harsh environments.

5. Advantages

Corrosion Resistance: Stainless steel sleeves provide excellent protection against rust and corrosion, making them suitable for challenging environments.

High Strength: The forging process ensures that these components can withstand significant loads and pressures.

Durability: Forged stainless steel sleeves are generally more resistant to wear and deformation compared to cast or machined components.

Versatility: Can be customized for various applications and requirements, ensuring compatibility with different systems

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :

_1733312730.jpg)