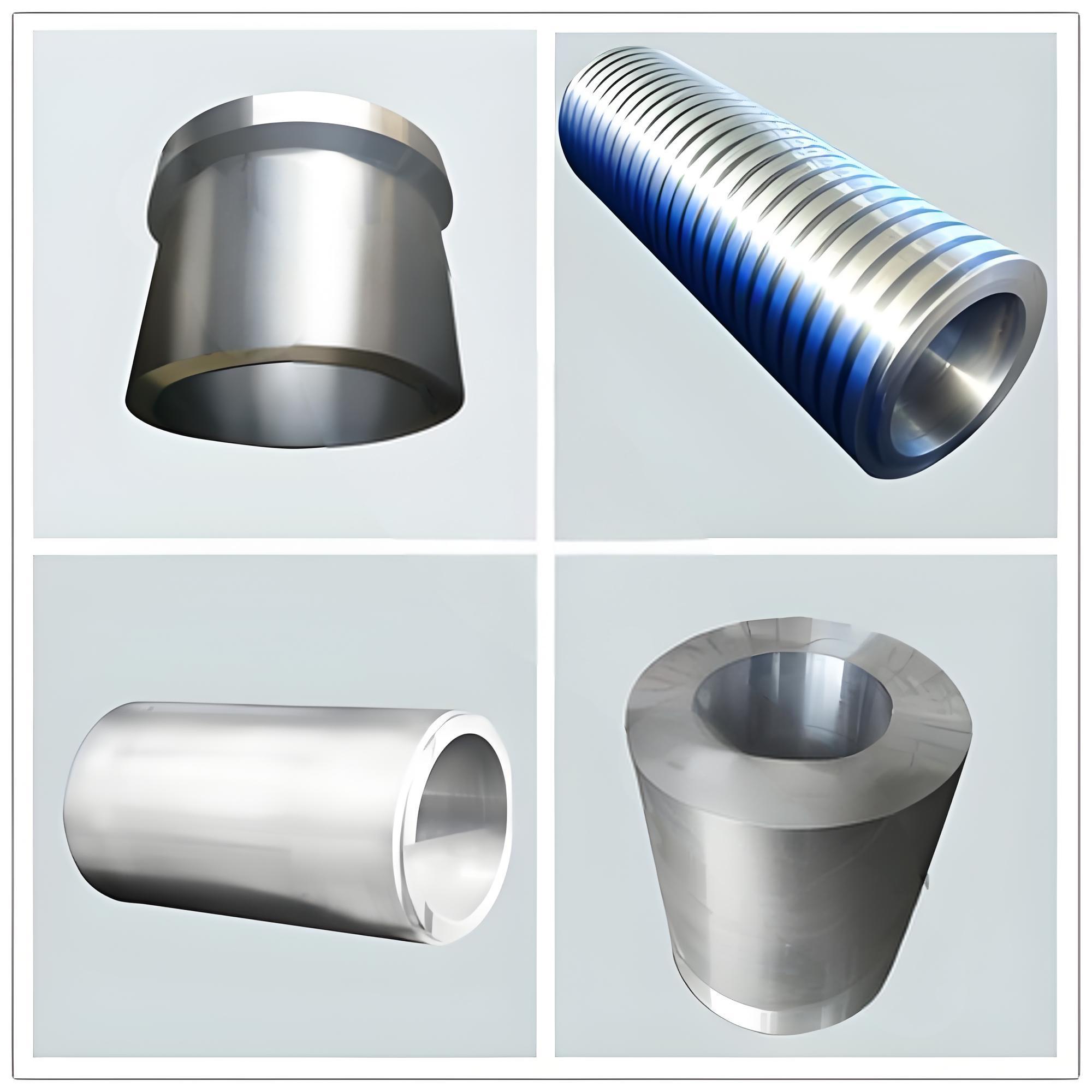

Forging Cylinder Tube Pipe Sleeve

Forging Cylinder Tube Pipe Sleeve

A forging cylinder tube pipe sleeve is a cylindrical component created through the forging process, specifically designed to serve as a sleeve for pipes or tubes. These sleeves enhance the structural integrity and performance of pipe systems in various applications.

Applications:

Forging cylinder tube pipe sleeves are used in several industries, including:

Oil and Gas: Providing connections in pipelines and ensuring leak-proof seals under high pressure.

Automotive: Used in engine components and exhaust systems for durability and strength.

Hydraulic Systems: Acting as protective casings for hydraulic lines and components.

Construction: Supporting structural integrity in various building applications.

Characteristics:

High Strength: Forged sleeves typically exhibit superior strength compared to non-forged counterparts, making them ideal for high-pressure applications.

Enhanced Durability: The forging process improves the material's toughness and fatigue resistance, prolonging the lifespan of the component.

Precision Fit: Designed to create a snug fit with corresponding pipes or tubes, ensuring effective sealing and reducing the risk of leaks.

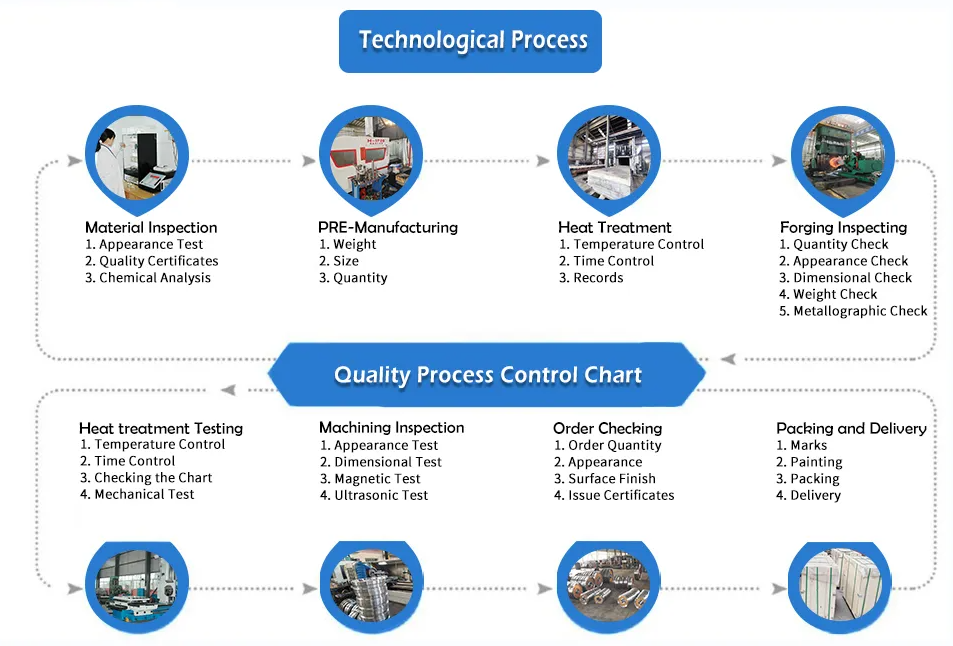

Forging Process:

Material Selection: Typically made from high-strength steel or alloys suited for specific environmental conditions.

Heating: The selected metal is heated to a malleable state, allowing it to be shaped without cracking.

Forging: The heated material is shaped using a forging press or hammer, creating the desired cylinder tube form.

Cooling and Finishing: After forging, the sleeve is cooled and may undergo additional processes such as heat treatment or surface finishing to enhance its properties.

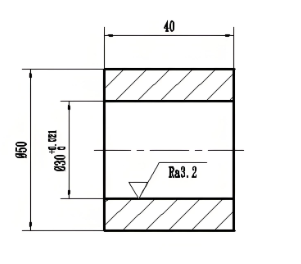

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :