Heat Treatment Sleeve Alloy for Mineral Equipment

Heat Treatment Sleeve Alloy for Mineral Equipment

Heat treatment sleeves made from alloy materials are specialized components designed to enhance the performance and durability of mineral processing equipment. These sleeves are subject to heat treatment processes to improve their mechanical properties, making them suitable for harsh operating conditions.

Applications:

Heat treatment sleeves are commonly used in various mineral processing equipment, including:

Crushers: To protect components from wear and impact during the crushing process.

Conveyors: As protective sleeves to reduce friction and wear on moving parts.

Drilling Equipment: To enhance the durability of parts exposed to abrasive materials.

Pumps: Used in slurry pumps to protect against corrosion and erosion.

Characteristics:

Material Composition: Typically made from high-performance alloys, such as stainless steel, tool steel, or other wear-resistant materials.

Heat Treatment Benefits:

Increased Hardness: Improves wear resistance, essential for handling abrasive materials.

Enhanced Toughness: Reduces the risk of cracking or failure under stress.

Improved Corrosion Resistance: Essential for applications in corrosive environments.

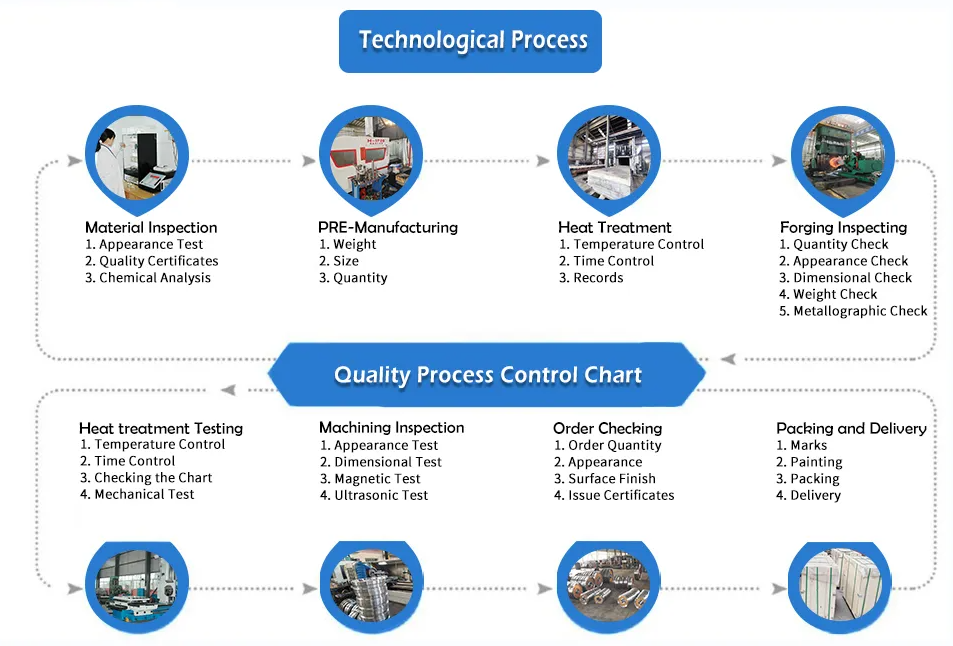

Heat Treatment Process:

Heating: The alloy is heated to a specific temperature to alter its microstructure.

Soaking: The material is maintained at this temperature for a designated time to ensure uniformity.

Quenching: Rapid cooling is applied to lock in the desired properties, often using water, oil, or air.

Tempering: A subsequent heating process to relieve stresses and enhance toughness while retaining hardness.

Data Needed for Quotation

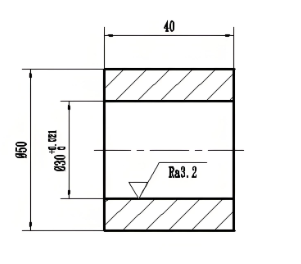

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc