Forged pipe fittings made from 1.4307 stainless steel

Forged pipe fittings made from 1.4307 stainless steel

1. Definition

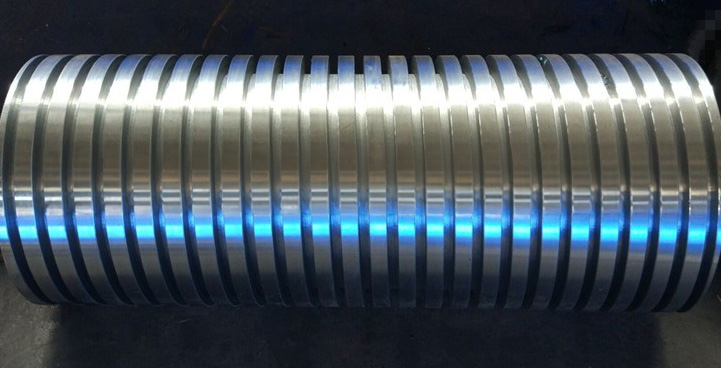

Forging of cylindrical components from 20MnMoD steel involves shaping the material into cylindrical forms that are used in various high-strength applications, particularly in pressure vessels and heavy machinery.

2. Materials

20MnMoD is a low-alloy steel known for:

Manganese (Mn): Enhances strength and hardenability.

Molybdenum (Mo): Improves strength at elevated temperatures and enhances toughness.

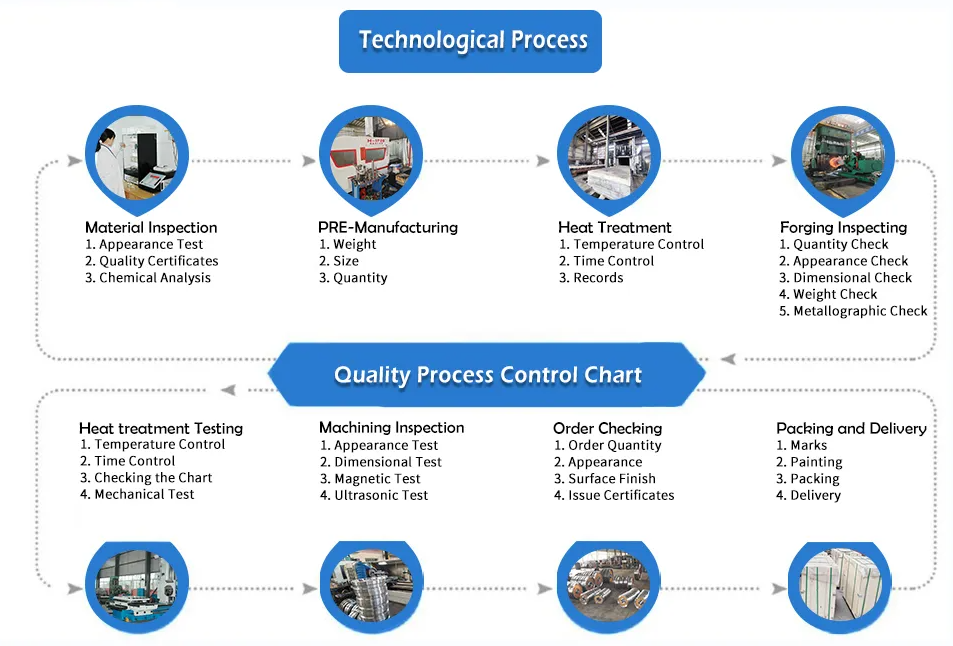

3. Manufacturing Process

Heating: The steel is heated to a suitable forging temperature, typically between 1000°C and 1200°C (1832°F to 2192°F), to ensure it is malleable.

Forging: The heated steel is then shaped using a press or hammer. This process helps refine the grain structure, resulting in improved mechanical properties.

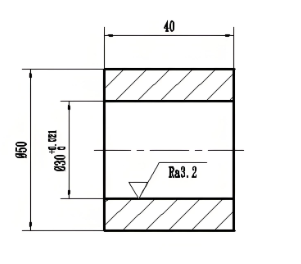

Machining: After forging, the components may undergo machining to achieve precise dimensions and surface finishes.

Heat Treatment: Post-forging heat treatments, such as normalizing or tempering, may be applied to enhance the mechanical properties, including toughness and ductility.

4. Applications

Cylindrical forged components made from 20MnMoD steel are commonly used in:

Pressure Vessels: For storing gases and liquids under high pressure.

Heavy Machinery: In components that require high strength and durability.

Pipelines: Especially in the oil and gas industry, where resistance to pressure and corrosion is critical.

5. Advantages

High Strength: Forged components exhibit superior strength and are capable of withstanding high loads.

Improved Toughness: The forging process enhances the toughness of the material, making it suitable for dynamic applications.

Corrosion Resistance: The molybdenum content provides good resistance to various corrosive environments.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :

_1733312730.jpg)

_1733312730.jpg)