Forged components for centrifugal casting molds

Forged components for centrifugal casting molds

1. Definition

Forged components for centrifugal casting molds are specialized tools used in the centrifugal casting process, where molten metal is poured into a rotating mold to create cylindrical parts. These components are essential for ensuring the precision and quality of the cast products.

2. Materials

These forged components are typically made from:

Carbon Steel: Known for its strength and cost-effectiveness, suitable for many industrial applications.

Alloy Steel: Such as 4140 or 4340, which provide enhanced toughness and wear resistance.

Tool Steel: Used for its hardness and wear resistance, ensuring durability during the casting process.

3. Manufacturing Process

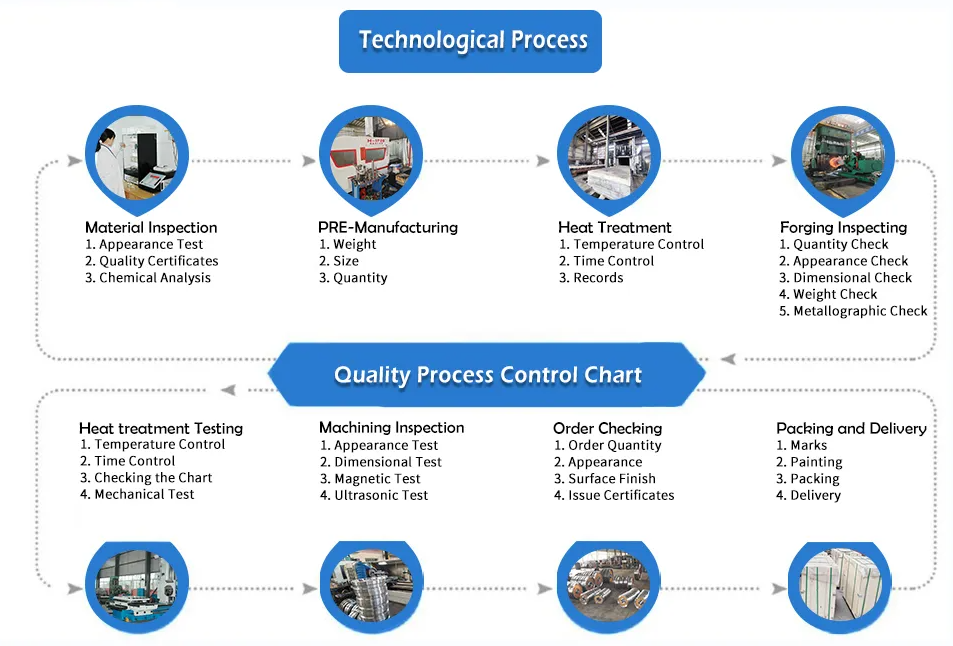

Forging: The raw material is heated and shaped under high pressure, enhancing the mechanical properties and refining the grain structure.

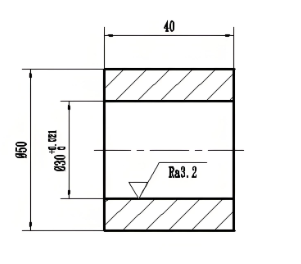

Machining: After forging, the components undergo precision machining to achieve the required dimensions and surface finishes necessary for effective mold operation.

Heat Treatment: Processes like quenching and tempering may be applied to improve hardness and overall performance, which is critical in high-stress applications.

4. Applications

Forged components for centrifugal casting molds are commonly used in:

Pipe and Tube Manufacturing: For producing high-quality, durable pipes and tubes in various industries, including oil and gas.

Aerospace Parts: In the production of lightweight and strong components.

Automotive Industry: For creating components that require high strength and precision.

5. Advantages

High Strength and Durability: Forged components can withstand the high stresses and temperatures of the casting process, ensuring reliable performance.

Improved Integrity: The forging process results in fewer defects and a more uniform structure compared to other manufacturing methods.

Cost-Effectiveness: While initial costs may be higher, the durability and longevity of forged molds can lead to lower overall production costs.

Customizability: Components can be designed to meet specific requirements for various casting applications, ensuring compatibility with different processes.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :

_1733312730.jpg)