Forged copper foil turnover sleeves

Forged copper foil turnover sleeves

1. Definition

Forged copper foil turnover sleeves are cylindrical components designed to support and facilitate the handling of copper foil during manufacturing processes. They are used to manage the storage, transportation, and processing of copper foil materials.

2. Materials

These sleeves are typically made from:

Copper Alloys: Commonly used for their excellent electrical and thermal conductivity, as well as corrosion resistance.

Brass: An alloy of copper and zinc that offers good strength and machinability.

3. Manufacturing Process

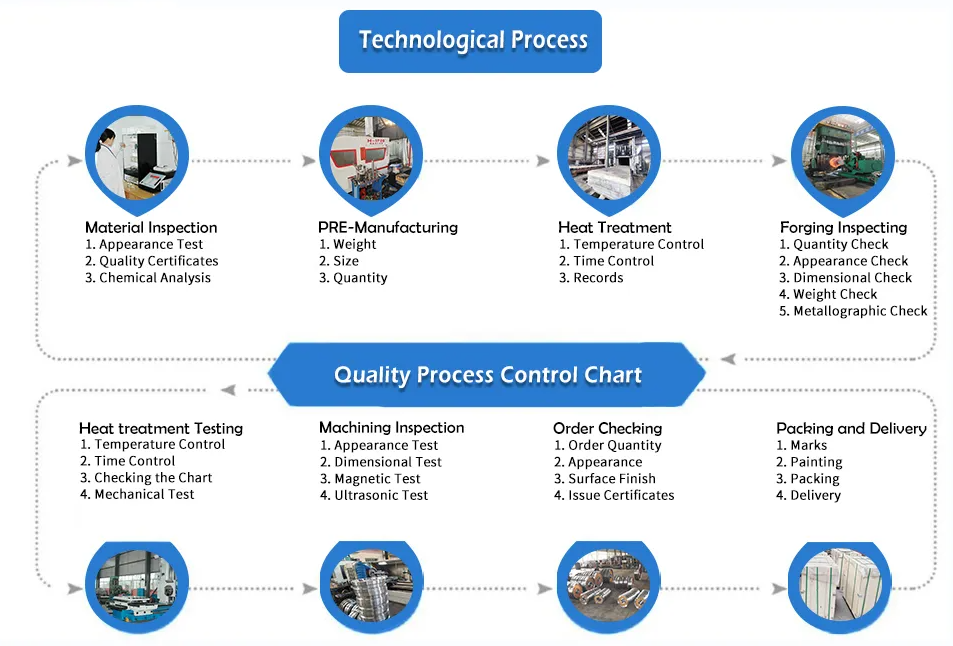

Forging: The copper or brass material is heated and shaped under high pressure. Forging enhances the mechanical properties and refines the grain structure, contributing to better performance.

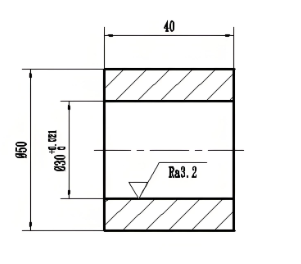

Machining: After forging, the sleeves may undergo precision machining to achieve specific dimensions and surface finishes necessary for their application.

Surface Treatment: Processes such as anodizing or coating may be applied to enhance corrosion resistance and surface durability.

4. Applications

Forged copper foil turnover sleeves are commonly used in:

Electronics Manufacturing: For handling and processing copper foils used in circuit boards and other electronic components.

Electrical Applications: In applications where high conductivity and reliability are critical.

Metalworking Industries: For managing the transportation and application of copper foil materials.

5. Advantages

High Strength: Forged components exhibit superior strength and durability, making them suitable for handling delicate materials like copper foil.

Excellent Conductivity: Copper and its alloys provide outstanding electrical and thermal conductivity, essential for many applications.

Improved Structural Integrity: The forging process results in fewer defects compared to cast components, ensuring reliability.

Customizability: Can be tailored to meet specific dimensions and performance requirements for various applications.

Data Needed for Quotation

1) Your own drawing

2) Your requirement on material and necessary dimensional data

3) Ask for recommend

Processing Materials

| Case Hardened Comparison Table | |||||||

| GB | ГOCT | EN | DIN | W.N. | JIS | AISI/SAE | |

| 15CrMn | 16MnCr5 | 16MnCr5 | 1.7131 | 5115 | |||

| 20CrMn | 20MnCr5 | 20MnCr5 | 1.7147 | 5120 | |||

| 12CrMo | 12XM | 13CrMo44 | 1.7335 | 4119 | |||

| 15CrMo | 15XM | 15CrMo5 | 1.7262 | SCM415 | |||

| 20CrMo | 20XM | 20CrMo5 | 1.7264 | SCM420 | 4118 | ||

| 25CrMo | 30XM | 25CrMo4 | 1.7218 | ||||

| 30CrMo | SCM430 | 4130 | |||||

| 35CrMo | 35XM | 34CrMo4 | 1.722 | SCM435 | 4135 | ||

| 42CrMo | EN19 | 42CrMo4 | 1.7225 | SCM440 | 4140 | ||

| 50CrMo4 | 1.7228 | ||||||

| 40Cr | 40X | 41Cr4 | |||||

| 38XC | |||||||

| 25Cr2MoV | 25X2M1Φ | 24CrMoV55 | 1.7733 | ||||

| 50CrVA | 50CrV4 | 1.8159 | SUP10 | ||||

| 31CrMoV9 | 1.8519 | ||||||

| GCr15 | 100Cr6 | 100Cr6 | 1.3505 | 52100 | |||

| 20CrNiMo | 20XHM | 20NiCrMo2-2 | 21NiCrMo2 | 1.6523 | SNCM220 | 8620 | |

| 20XH3A | |||||||

| 20X2H4A | |||||||

| 17CrNiMo6 | 1.6587 | ||||||

| 18CrNiMo7-6 | 1.6587 | ||||||

| 34CrNiMo6 | 1.6582 | VCN150 | |||||

| 34NiCrMo16 | 35NiCrMo16 | 1.2766 | |||||

| 30CrNiMo8 | 1.658 | VCN200 | |||||

| 39NiCrMo3 | 1.651 | ||||||

| 34CrAlNi7 | 1.855 | ||||||

| 38CrMoAl | 38X2MОA | 41CrAlMo7 | 1.8509 | ||||

| 40CrNiMo | EN24 | 40NiCrMo8-4 | 1.6562 | SNCM439 | 4340 | ||

| 40CrNi | 40XH | 40NiCr6 | 1.5711 | ||||

| 20CrMnMo | 18XTM | SCM421 | |||||

| 40CrMnMo | 40XTM | SCM440 | |||||

| 30XTCA | |||||||

| 38XTH | |||||||

| 40XH2MA | |||||||

| 40X2H2MA | |||||||

| 38XH3MA | |||||||

| 38XH3MΦA | |||||||

Processing technology:

Application areas:

Automotive transmissions, medical equipment, metallurgical machinery, lifting equipment, ore equipment, power equipment, light industry equipment, etc

Packaging :

_1733312730.jpg)